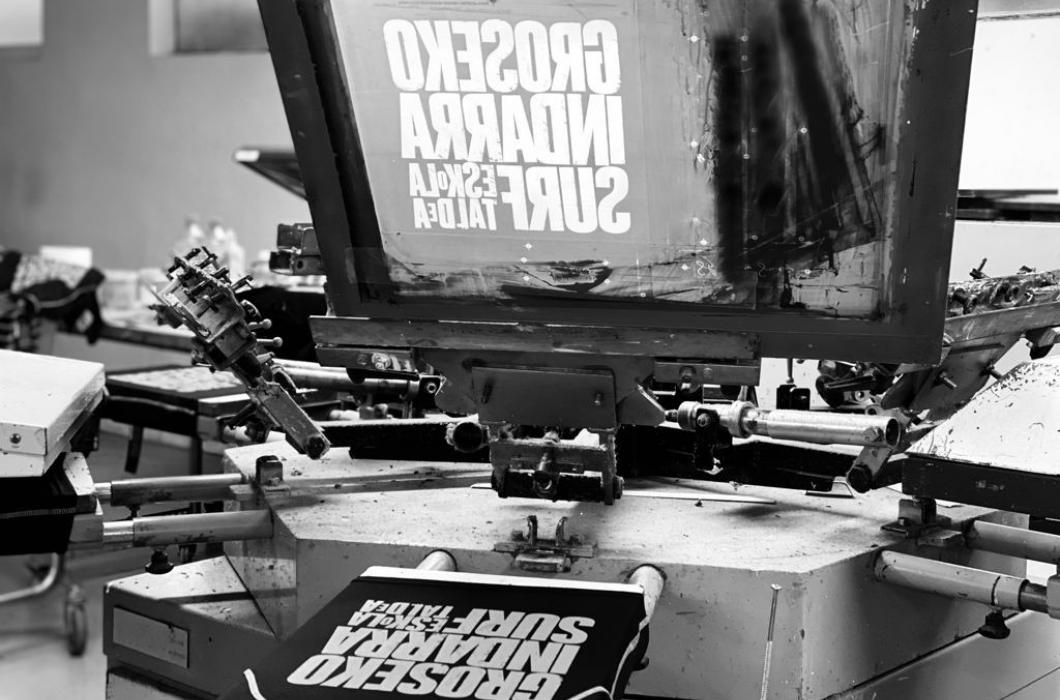

Textile silkscreen printing

The silk-screen printing technique on fabric is one of the oldest and most popular marking methods in the world.

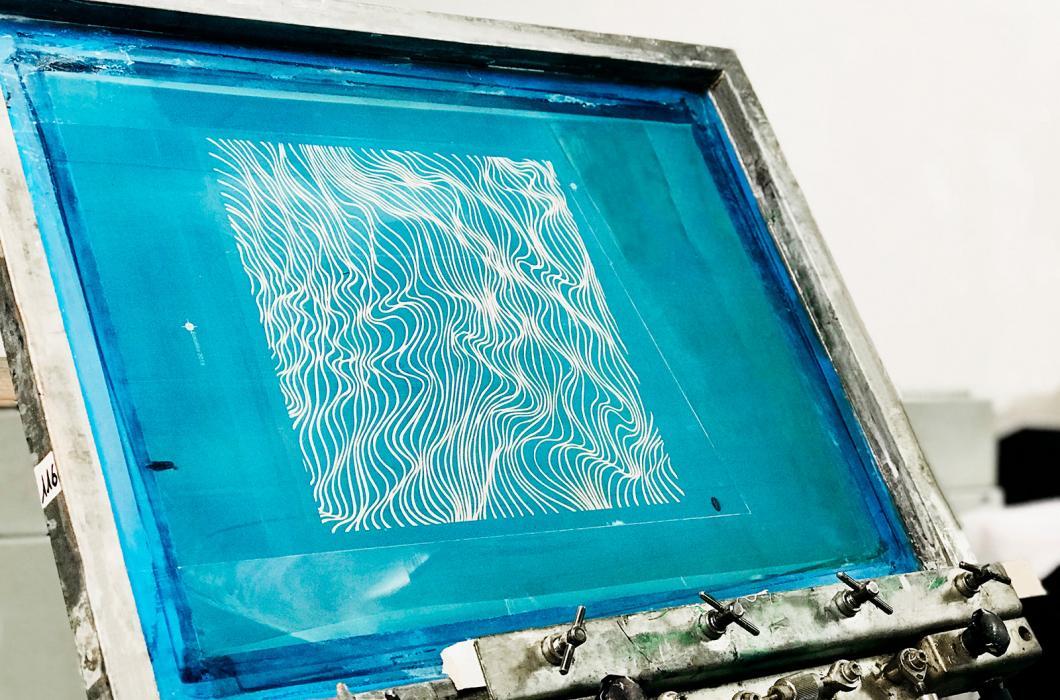

This is a stamping technique that consists of using a mesh screen to transfer an image, reproducing it on a textile surface. With a scraper, the dye goes through the mesh or template to the fabric.

This technique's main feature is that it is more versatile as far as ink and colour are concerned. This is the technique that provides the greatest degree of adherence and durability on any textile fabric.

The results obtained with this technique are highly satisfactory. Different inks can be used, rendering different effects to play with finishes that are different to the touch and to the eye.

With the aid of different mechanisms, this process can be either manual or automatic, where the screenprinter's intervention, experience and skill is essential. As such, the technique's has an important artisan component, and the finish is 100% professional.

The main advantages of using silkscreen printing to stamp an image on a jacket, T-shirt, shirt, cloth bag, knapsack, sweatshirt, or similar, is that:

- The print is more resistant after many washes

- A colour very close to the desired colour can be achieved

- It provides many possibilities to the touch

- You can play with optical sensations: weave, shine, matte, etc.

There are many traditional textile compositions that can be printed on: cotton, cotton+polyester, polyester, nylon, viscose, wool, lycra, polyamide, neoprene, stiffened fabrics, PVC, etc.

This is the most advisable for a design with colours and flat surfaces, and for large series, since it is more economical.